|

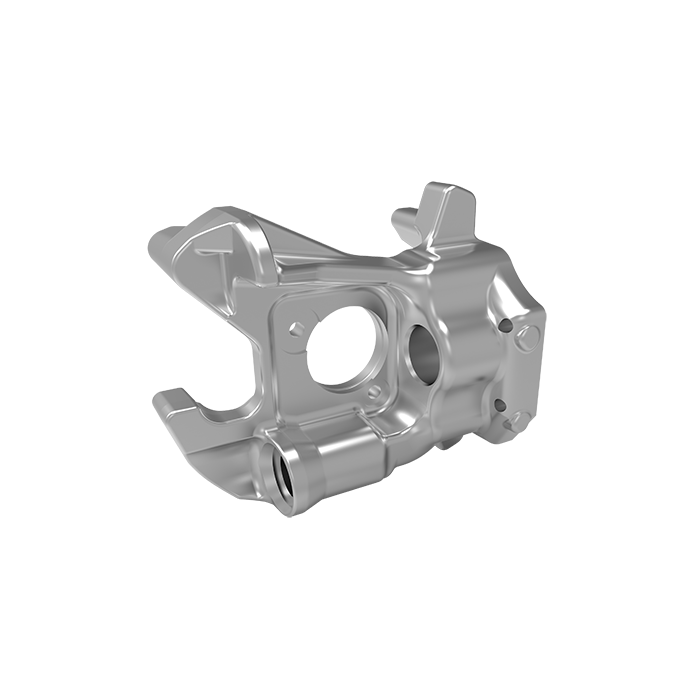

Crankcase is the heavy, rugged part that has integrated cylinder block and four inch discharge line, especially designed to dampen the pressure fluctuation of the discharged gas. It works as the base on which all the rotating parts; valve group and cylinder head are mounted. This is casted from Grey cast iron undergoing special heat treatment to improve its machining process.

|

|

Property:

- Material before annealing: Grey cast iron EN-GJL-200 according DIN EN 1561

- Annealing process is to change the structure from essentially pearlitic one to essentially ferritic one with effect of change of mechanical properties

- Casting microstructure according EN ISO 945 shall be essentially ferritic

- Mechanical properties after annealing: Hardness measured on component: 135-185HB 5/750

- Surface: Sand blasted, no sharp casting burr, No burr of parting line shifting and gating, smooth, clean, no cracks, no cavities, no pores, no blisters, free of scale and loose particles (like molding sand), oiled for rust protection.

|